Our manufacturing processes

We specialize in pultrusion, pull-winding, and continuous lamination manufacturing. These continuous processes provide many benefits including repeatable quality and volume output.

What is pultrusion?

Pultrusion is a continuous manufacturing process resulting in a steady output of a composite profile which is cut to length at the end of the process. It is called pultrusion because the profile being produced is actually pulled through the process.

The pultrusion process has four main process steps; reinforcement alignment and resin impregnation, shaping and heating in a die; the pulling process, and finally cutting.

The process starts by pulling continuous reinforcements through a resin bath to wet out the fibers. The process is controlled to ensure full wetting out of the fiber reinforcement. Excess resin is then removed to expel any trapped air and to compact the fibers. The impregnated reinforcement is passed through preforming guides to align the reinforcement before entering the heated die. The temperature of the die is carefully controlled to ensure that the composite is fully cured.

Pulling is achieved using either a moving carriage with adjustable clamps or a caterpillar puller system. The fully cured section can be cut to length after the puller system, or if size and shape permit, be wound onto a drum as a continuous length. The only limitations on length for cut sections are storage and transportation.

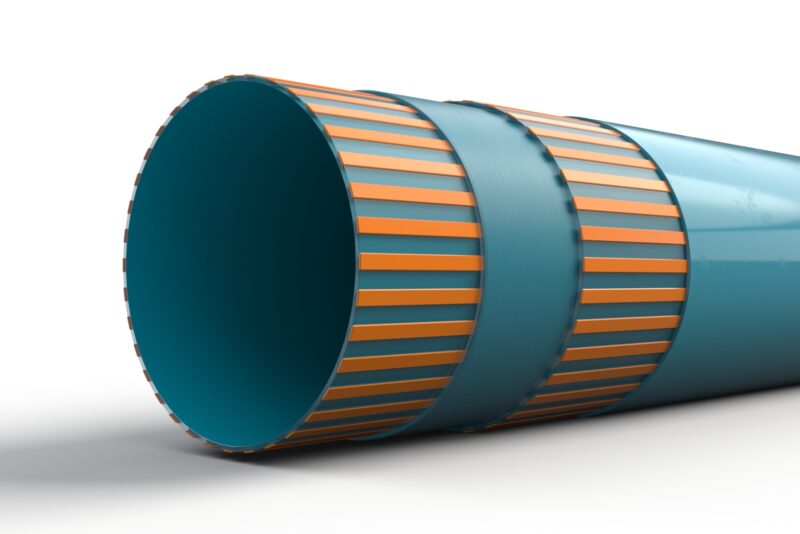

What is pull-winding?

Pull-winding combines the two techniques of pultrusion and continuous filament winding resulting in a profile with excellent hoop strength, logitudinal strength and modulus, with smooth surface finish.

In addition to the unidirectional alignment of fibers, the pull-winding process uses helical winding of reinforcements resulting in both the ability to guide unidirectional fibers as well as helical winds (from a few degrees up to 90 degrees). This mix of fiber directions allows for composite advantages such as thinner walls or to meet specific strength or stiffness requirements.

The pull-winding manufacturing process is a continuous process resulting in a steady output of a composite profile which is cut to length at the end of the process. It is called pull-winding because the profile being produced is first “wound” helically with reinforcing fibers (in addition to unidirectional fibers) and then is pulled through the process.

The pull-winding process has four main process steps; reinforcement alignment and resin impregnation, shaping and heating in a die; the pulling process, and finally the flying shear cutting.

In the first step, reinforcing fibers, mats, and fabrics are precisely guided towards the die and impregnated with the prescribed resin. Next the fibers are pulled into a carefully controlled heated die in the shape of the desired profile. The resin is thermally set in this process, creating the desired composite profile.

This profile is then used to pull the reinforcements continuously through the die. Pulling mechanisms grab (friction hold using adjustable clamps or a caterpillar puller system) the newly formed composite profile and pull it in a continuously repeating process.

Finally the finished composite profile is cut to length in line with the continuous movement of the process.

What is continuous lamination?

Continuous lamination is used to produce very thin (from 0.3mm up to 1.1mm) and or very wide (approximately 1200mm) laminates. The process begins with aligning and impregnating reinforcements with resin which are then pressed and guided into the desired lay-up. This lay-up may be comprised of several reinforcing layers depending on the strength, stiffness, and other required mechanical properties.

Next the lay-up is pressed and cured under pressure and heat to achieve the desired mechanical properties.

Finally the composite laminate is wound onto a drum (spooled) for shipment or for further processing.