Composite Solutions

Solutions

For more than 60 years, we’ve provided expertise to industries in over 50 countries.

Whatever your design challenge is, we’ll help you find your composite solution.

Transportation

Make stronger, lighter and more efficient vehicles with internal and external composite profiles and stiffeners.

Telecommunication

Keep 5G data flowing with long life–cycle Exel Smart City composite solutions.

Infrastructure

A wide range of applications, from frangible composite lighting masts for airports to corrosion–resistant waste water solutions, composites play an important role in keeping infrastructure applications working.

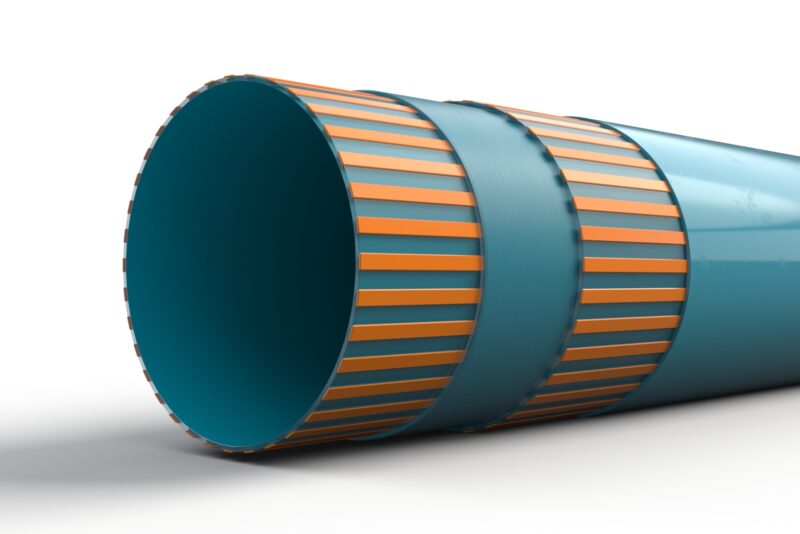

Machinery and electrical

From light weight carbon fiber arms for delta robots, to insulating components for electric motors and generators.

Equipment and other industries

The strength, lightness and durability of composites make great solutions for everything from tool handles to sporting goods.

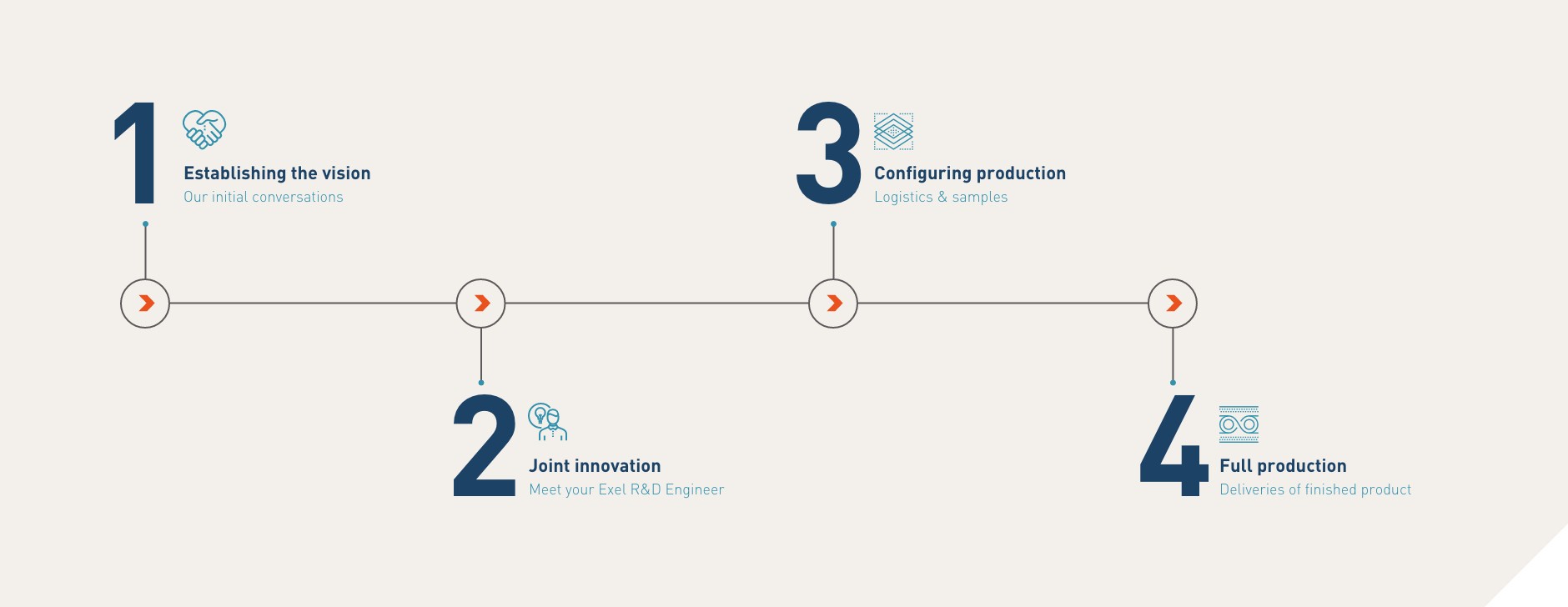

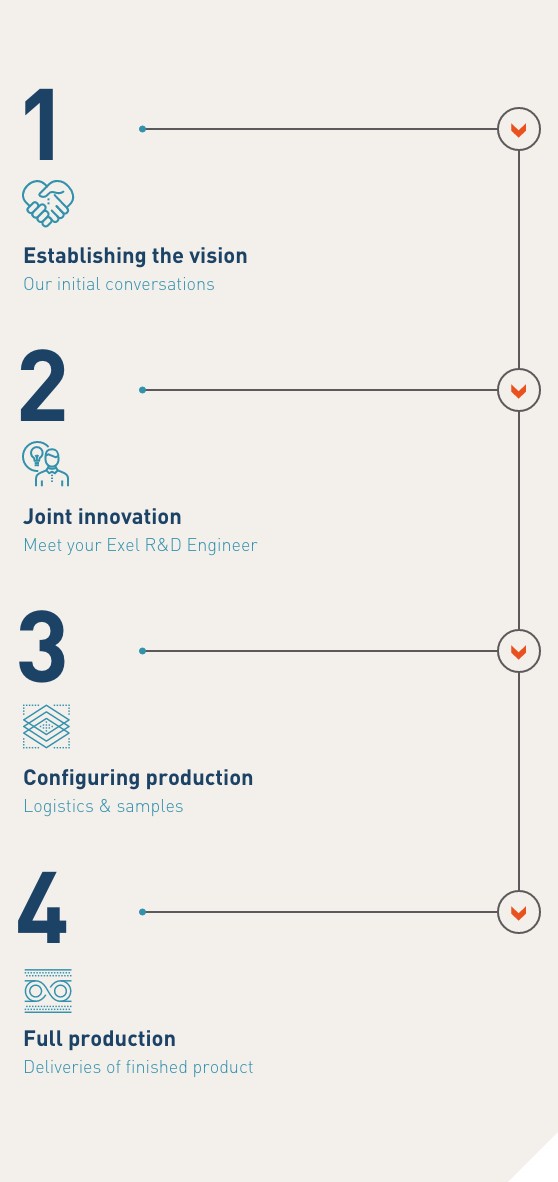

A partnership approach

We want you to have the right forward-thinking composite solution to fit your exact specifications and needs. Working with many different customers over the past 60 years has given us a lot of experience, so there’s a good chance we’ve got the relevant answers.

We work collaboratively with you to understand the technical requirements and application of your product. We then apply our fiber technology, chemistry and process know–how to deliver a forward thinking, cost–efficient solution to meet your needs and add value to your business.

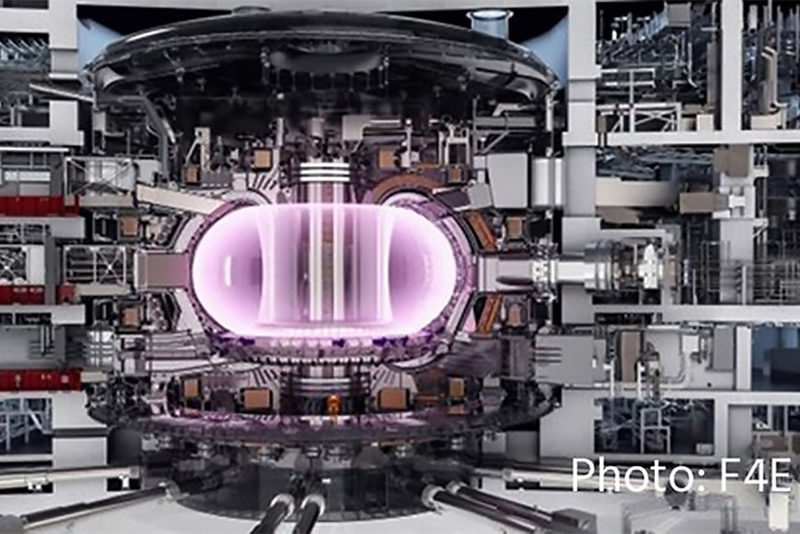

Our experience

Discover how our recent collaborations created innovative composite applications for industries across the world.