Composite solutions for electrical power transmission & distribution

Composite solutions for electrical power transmission & distribution

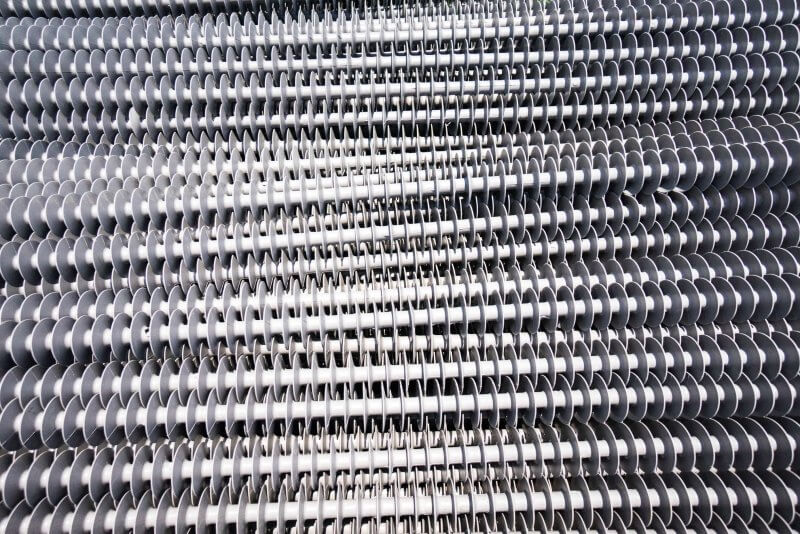

Composites are transforming the electrical industry by combining high-performance insulation with exceptional structural strength. Materials such as fiber glass and carbon fiber play a critical role in today’s power transmission and distribution networks, offering durability, lightweight performance, and resistance to corrosion.

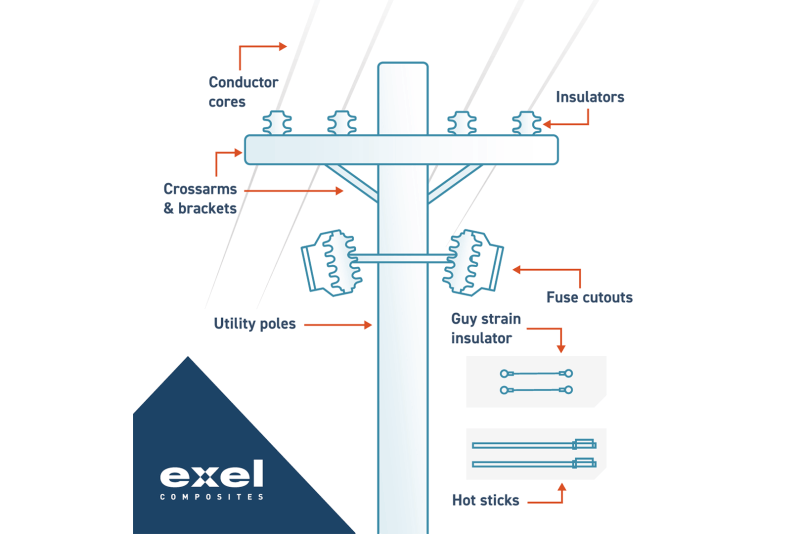

Depending on the requirements, composites can serve as both insulators and conductors, making them highly versatile for a wide range of electrical applications. They are used in conductor cores, insulating rods, surge arresters, long rod insulators, line posts, utility poles, and cross arms. In transformers, composites provide reliable support and insulation structures that improve efficiency and extend service life.

Composites also deliver safety and compliance advantages. For example, composite rail joints meet strict European standards while eliminating the need for welding or chemicals, and insulating poles provide electrical workers with safe, UV- and wear-resistant tools for working on energized lines. Explore our range of composite electrical applications below.

Why choose pultruded composites for electrical applications?

Pultruded composites are rapidly becoming the preferred choice for conductor cores, insulators, utility poles, cross arms, and hot sticks. Compared to traditional materials like steel, aluminum, or porcelain, they offer unmatched performance, safety, and durability.

Key advantages of pultruded composites:

- Superior electrical insulation: Non-conductive by nature, glass fiber composites reduce accident risks and improve safety across electrical systems.

- Lightweight, high strength: Stronger than steel by weight, yet easier to transport, install, and maintain.

- Corrosion and weather resistance: Ideal for coastal, industrial, and other harsh environments where metals fail.

- Durable under extreme conditions: Resistant to UV, chemicals, high voltages, and mechanical impacts such as earthquakes, gunfire, or accidental collisions.

- Long service life, low maintenance: Extended lifespan reduces downtime and lowers lifecycle costs.

- Consistent quality with pultrusion: Continuous, automated production delivers cost-effective, high-volume output with uniform quality.

Unlike porcelain insulators, composite insulators do not rupture or explode, even under extreme stress. By choosing pultruded composites, you gain infrastructure that is safer, more efficient, and built for the demands of modern power grids.

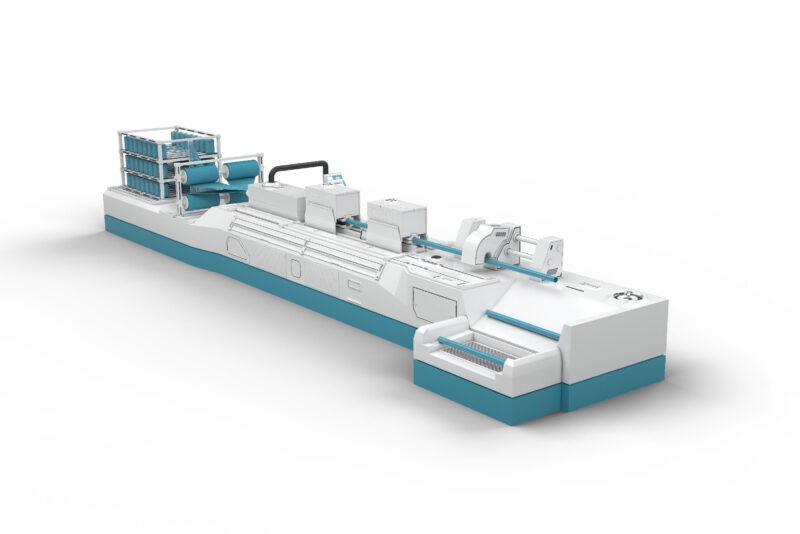

Pultrusion for electrical applications

Pultrusion is the advanced manufacturing process behind Exel’s composite solutions for the electrical industry. It is a continuous, automated method that produces strong, lightweight profiles with consistent quality, ideal for conductor cores, insulators, utility poles, cross arms, and hot sticks.

Pultruded composites offer high strength-to-weight ratios, excellent electrical insulation, and resistance to corrosion, UV, and chemicals. The process allows for high-volume, cost-effective production while enabling customization of designs, lengths, and technical properties to meet demanding electrical standards.

By combining performance with scalability, pultrusion makes it possible to deliver reliable, durable, and safe composite components that improve efficiency and reduce lifecycle costs across modern power grids.

Frequently asked questions about composite solutions for electrical power transmission & distribution (FAQ)

Q1: What composite solutions for electrical applications does Exel offer?

Exel Composites provides a wide range of pultruded solutions, including composite conductor cores, insulators and rods, utility poles, cross arms, hot sticks, and rail joints, as well as other custom solutions. All products are engineered for durability, safety, and performance in demanding electrical environments.

Q2: What are the benefits of using composite materials in electrical applications?

Composites combine lightweight strength, corrosion resistance, and electrical insulation. They extend service life, reduce maintenance, and offer safer, more efficient alternatives to wood, steel, or porcelain.

Q3: Why are composite utility poles better than wood, steel, or concrete poles?

Composite utility poles are lighter, corrosion-resistant, and longer-lasting. They are easy to transport and install, especially in remote areas, while providing superior durability against rot, insects, and harsh weather.

Q4: What makes composite insulators safer than porcelain insulators?

Unlike porcelain, composite insulators do not shatter or explode under stress. They withstand mechanical impacts, earthquakes, vandalism, and extreme weather, providing safer and more reliable performance.

Q5: What is pultrusion and why is it ideal for manufacturing composite electrical components?

Pultrusion is a continuous manufacturing process that produces high-quality composite profiles with consistent properties. It allows for cost-effective, high-volume production and the flexibility to customize designs.

Q6: What voltage levels can composite handle?

Composite materials are versatile and can be used across a wide range of voltages in electrical distribution and transmission systems:

- Low Voltage: Composites are used in applications such as insulating rods and components in low-voltage systems, typically up to 1 kV.

- Medium Voltage: They are also suitable for medium-voltage applications, which generally range from 1 kV to 36 kV.

- High Voltage: Composites are extensively used in high-voltage systems, including overhead transmission lines and substations, where voltages can range from 36 kV to 765 kV and beyond.

- Extra High Voltage (EHV): For extra high voltage applications, composites can handle voltages above 765 kV, ensuring reliable performance and insulation.

These materials are chosen for their excellent electrical insulation properties, mechanical strength, and resistance to environmental factors, making them ideal for a wide range of voltage levels.

Q7: How do composites manage EMC interference?

Composite materials handle electromagnetic compatibility (EMC) interference effectively through several mechanisms:

- EMI Shielding: Composites can be designed to block electromagnetic interference (EMI) by incorporating conductive fillers like carbon fibers or metal particles. These fillers help absorb and reflect electromagnetic waves, preventing them from interfering with sensitive electronic components.

- Absorption: Some composites are engineered to absorb electromagnetic waves rather than reflect them. This reduces the amount of interference that can affect nearby devices.

- Conductive pathways: By creating conductive pathways within the composite material, it can help dissipate electromagnetic energy, reducing the impact of EMI.

- Layered structures: Composites can be manufactured with multiple layers, each designed to target different frequencies of electromagnetic waves. This multi-layer approach enhances the overall shielding effectiveness.

These properties make composites a great choice for applications requiring robust EMC performance, such as in aerospace, automotive, and telecommunications industries.

Q8: Can composite products be customized for specific electrical infrastructure needs?

Yes. As the manufacturer, Exel can adapt designs, lengths, and technical features to meet customer requirements, ensuring each solution fits the intended application.