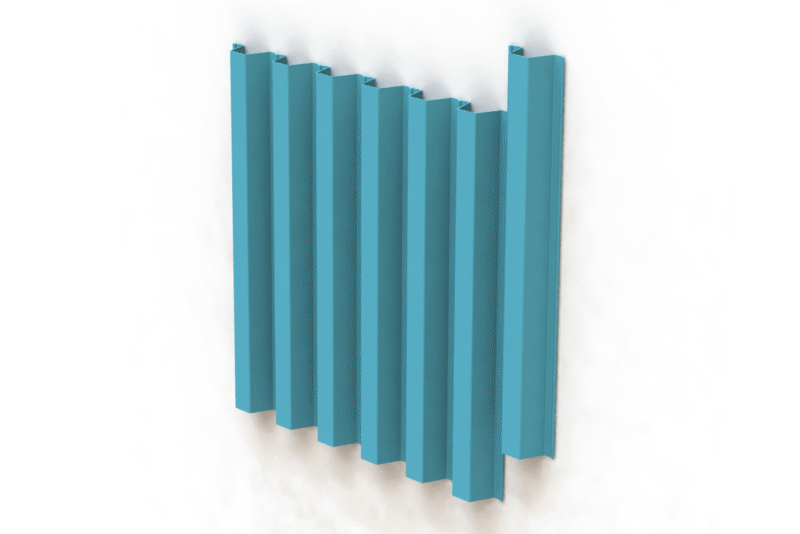

Composite sheet piles | FRP sheet piling solutions for corrosion resistance, strength & sustainability in demanding environments

Engineered for tough environments with FRP sheet piles

Exel Composites delivers high-performance composite sheet piles designed to withstand the most demanding construction and marine environments. Our FRP sheet piles offer a superior alternative to traditional steel and PVC materials, providing enhanced corrosion resistance, lightweight handling, and long-term durability.

Glass fiber reinforced sheet piles form interlocking vertical barriers that stabilize soil, resist water ingress, and protect against erosion. From retaining walls to flood defenses, composite sheet piles are a cornerstone of modern, sustainable construction.

Why FRP sheet piles are the future of civil and marine construction

Corrosion-resistant in harsh environments

Our FRP sheet piles are built for longevity in aggressive settings like coastal zones, waterways, and contaminated soils. Unlike steel, which rusts, glass fiber reinforced sheet piles maintain structural integrity over decades.

Lightweight, yet structurally strong

Composite sheet piles weigh significantly less than steel, simplifying transportation and installation. This reduces labor and machinery costs, especially in hard-to-reach locations or environmentally sensitive areas.

Extended service life with minimal maintenance

FRP sheet piles offer up to 75 years of service life with minimal upkeep. Their non-corrosive nature means reduced maintenance costs and fewer disruptions throughout the project lifecycle.

Thermal & environmental stability

Glass fiber reinforced sheet piles perform reliably under extreme temperatures, UV exposure, and chemical conditions. This makes them ideal for flood-prone regions, industrial sites, and marine installations.

Customizable, aesthetic & durable

With options for color, texture, and profile design, composite sheet piles provide architects and engineers with the flexibility to meet structural and visual requirements. Unlike steel, which needs coating, or PVC that fades, FRP sheet piles retain their finish and form.

High strength & stiffness

Using continuous pultrusion technology, Exel manufactures FRP sheet piles reinforced with E-glass fibers and thermoset resins for high tensile strength and stiffness. The result? Stronger, more reliable composite sheet piles for all your critical infrastructure needs.

Applications for composite sheet piles

Infrastructure sheet pile applications

- Retaining walls: Maintain soil stability during excavation

- Flood defense: Use FRP sheet piles as robust water barriers

- Shoring & excavation support: Ensure trench and foundation safety

- Foundation support: Reinforce weak or shifting soils

- Noise & vibration barriers: Shield construction zones and transit corridors

- Cut-off & containment walls: Block groundwater and isolate pollutants

Marine & coastal sheet pile applications

- Bulkheads and seawalls: Protect coastlines with glass fiber reinforced sheet piles

- Piers and docks: Create stable platforms with corrosion-resistant support

- Breakwaters: Use composite sheet piles to dampen wave impact

- Groin or groyne: Use composites sheet piles for to build a rigid structure perpendicularly from an ocean shore river bank to interrupting water flow and limiting the movement of sediment.

- Harbor construction: Build or expand with long-lasting FRP walls

- Erosion control: Stabilize slopes and shorelines with lightweight durability

- Waterfront development: Design coastal parks and promenades with aesthetic flexibility

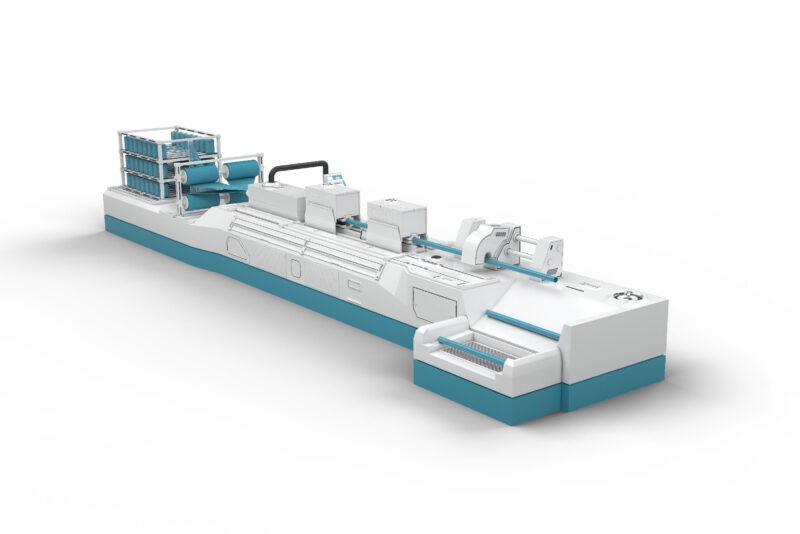

How our composite sheet piles are made

Exel’s FRP sheet piles are produced using continuous pultrusion, a precise method where E-glass fibers are saturated in thermoset resin (polyester, vinylester, or polyurethane) and cured into uniform profiles. This results in consistent, strong, and durable glass fiber reinforced sheet piles. Read more about pultrusion here.

Reinforcement includes:

- Unidirectional rovings

- Woven fabrics

- Continuous filament mats

This structure ensures every composite sheet pile delivers the mechanical strength and corrosion resistance required for modern infrastructure challenges.

Flood protection starts with the right material

With flooding responsible for 40% of all natural disaster damages globally, selecting the right material is critical. Glass fiber reinforced sheet piles provide unmatched performance in resisting water ingress, corrosion, and soil movement over time. Compared to traditional materials, FRP sheet piles deliver:

- Longer life spans

- Reduced maintenance costs

- Lower overall environmental impact

Make flood-resilient infrastructure part of your design from day one with composite sheet piles engineered for the future.

Read more about how composite materials fit the seaside infrastructure.

Frequently asked questions about FRP composite sheet piles

Q1: What is a composite sheet pile?

A composite sheet pile is a structural barrier made from fiber-reinforced polymer (FRP) materials, such as E-glass fibers embedded in thermoset resin. These piles interlock vertically to form continuous walls used in soil retention, flood protection, erosion control, and other civil and marine construction projects.

Q2: What are the most common applications for composite sheet piles?

Composite sheet piles are commonly used in infrastructure projects like retaining walls, flood defenses, and excavation support, as well as in marine applications such as seawalls, piers, breakwaters, and erosion control structures.

Q3: How do FRP sheet piles compare to steel sheet piles?

FRP sheet piles offer superior corrosion resistance, lighter weight, and lower long-term maintenance costs compared to steel. While steel has high initial strength, it is prone to rust and requires coatings and frequent upkeep, especially in marine environments. Glass fiber reinforced sheet piles from Exel maintain structural integrity for decades without these issues.

Q4: Are FRP sheet piles suitable for marine or coastal projects?

Yes. FRP composite sheet piles are ideal for marine and waterfront applications. Their resistance to saltwater, UV exposure, and chemical degradation makes them well-suited for seawalls, piers, docks, marinas, and erosion control structures.

Q5: Can FRP sheet piles be installed using traditional piling equipment?

Absolutely. Exel’s FRP sheet pile profiles are designed to be compatible with standard sheet pile installation methods and equipment. Their lightweight nature can actually simplify installation compared to heavier steel piles.

Q6: How long do composite sheet piles last?

FRP sheet piles can last up to 75 years or more, depending on environmental conditions and installation. Their corrosion-resistant properties help reduce maintenance and extend the functional lifespan well beyond that of steel or PVC alternatives.

Q7: What resins are used in FRP sheet piles?

We use high-performance thermoset resins such as polyester, vinyl ester, and polyurethane. The choice of resin can be tailored to match your project’s environmental and structural requirements.

Q8: Are custom dimensions or finishes available?

Yes. Exel Composites offers a range of customizable FRP sheet pile profiles, including options for width, depth, wall thickness, surface finish, and color. Contact our team to discuss a tailored solution for your application.

Q9: Are glass fiber reinforced sheet piles sustainable?

Glass fiber reinforced sheet piles offer long service life, minimal maintenance, and lightweight handling—all of which reduce environmental impact over the product lifecycle. They also eliminate the need for corrosion-resistant coatings and can reduce fuel usage during transportation and installation.

Q10: How are FRP sheet piles made?

FRP sheet piles are manufactured using a process called a continuous process called pultrusion. This involves pulling E-glass fibers through a resin bath where they are saturated with a thermosetting resin (such as polyester, vinylester, or polyurethane). The impregnated fibers are then pulled through a heated die that shapes and cures the material into a rigid profile. This method creates glass fiber reinforced sheet piles with consistent cross-sections, high tensile strength, and excellent resistance to corrosion and environmental stress.