Composite tubes enable geothermal energy storage

Exel has completed a R&D project with geothermal technology expert QHeat to provide composite tubes to store excess heat energy at the Lounavoima waste incineration plant in Salo, Finland. Simulations suggest the glass fiber reinforced polymer (GFRP) tubes enable plant operators to store 14 GWh of heat in underground wells two kilometers down in the granite bedrock.

Prior to installing a heat storage system, the Lounavoima plant released its excess heat into the air during the summer. When ambient temperatures fell to -20°C in the Finnish winter, its emissions increased because of the supplementary oil burners needed to supply heat at peak times. The energy saved by improving the plant’s storage efficiency equates to the heating requirements of 700 detached houses per year.

“60 per cent of all EU heat production comes from fossil fuels, and the remaining 40 per cent is still mostly combustion, like natural gas or waste incineration,” explained Erika Salmenvaara, CEO at QHeat. “In the context that half of global energy use is for heating, we see the environmental gains that electrification of heating can provide.

“It’s not perfect,” Salmenvaara continued. “Electrification of heating puts significant strain on the world’s ageing power transmission infrastructure, but innovative engineering can help there too. Grid-enhancing technologies are advancing rapidly and, besides, heat pumps deliver up to 600 per cent more energy efficiency than using electricity directly.”

Exel Composites’ R&D department worked closely with QHeat’s engineers to tailor the composite tubes to the job’s specific environmental and performance requirements. The two teams went through several iterations, optimizing for sizing, connection methods, and thermal insulation vs mechanical strength trade-offs.

GFRP is well-suited to the pressure and temperature involved with underground applications. The insulating capacity was a great focus for the partnership, ensuring energy efficiency in heat transfer is as high as possible.

“Heat preservation combined with the right mechanical performance was the biggest criterion to satisfy with these pipes,” said Tiina Uotila, technical sales manager at Exel Composites. “However, we collaborated with QHeat to understand how we could make them easier to assemble and install, and to make sure that we have a defined, sustainable end-of-life route.

“Instead of going to landfill, these pipes will be co-processed into cement, where the reinforcement replaces raw materials and matrix replaces fuels,” explained Uotila.

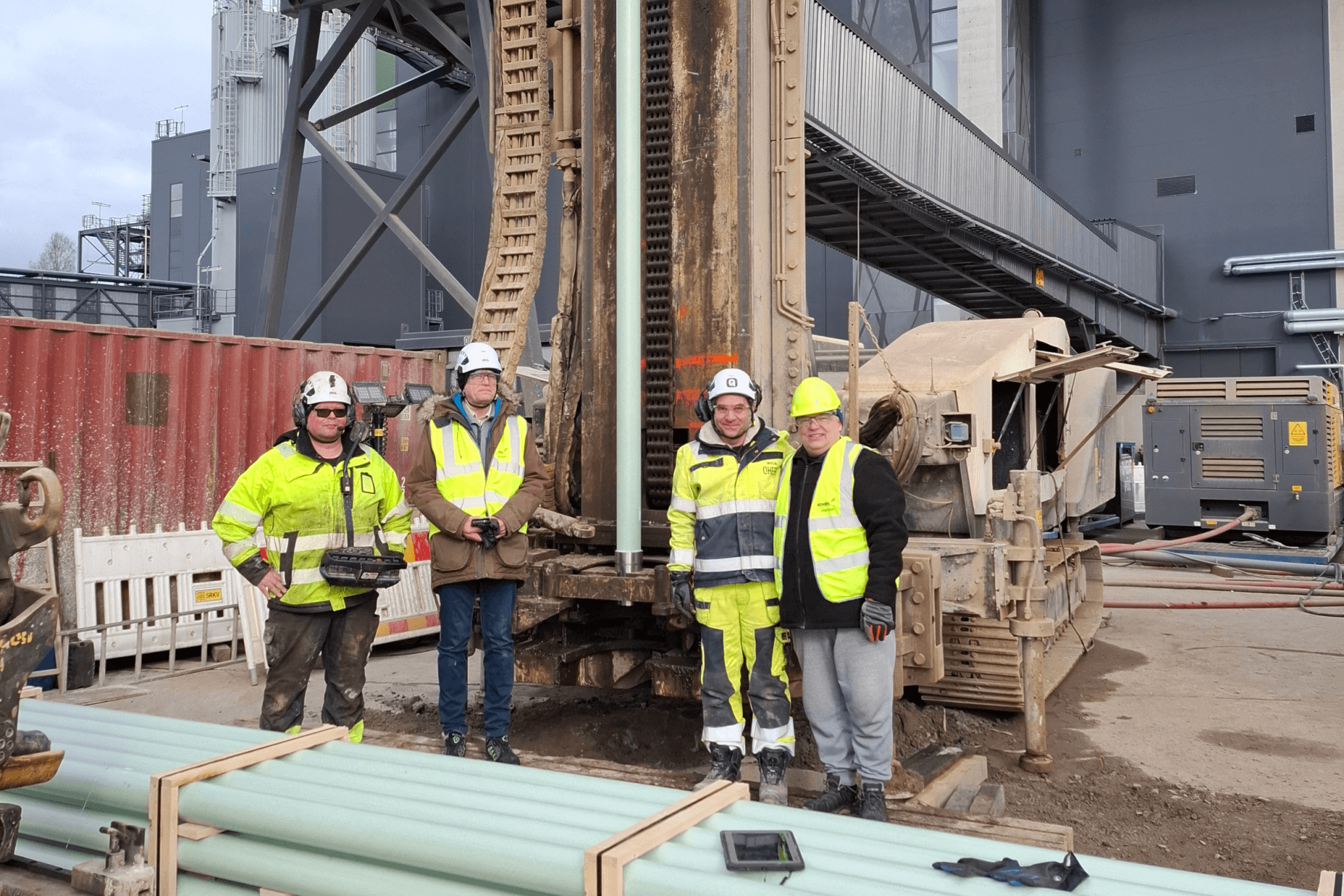

“I was impressed that Exel Composites’ head designer came on site with us in Salo to see the first pipes installed,” remarked Salmenvaara. “I also had the chance to visit Exel’s Mäntyharju factory in Finland. Then I understood its expertise, its design capabilities and the quality of its products.