Composite conductor cores

Transforming power transmission with composite conductor cores

The demand for more efficient, reliable, and sustainable electricity transmission is greater than ever. Transmission System Operators (TSOs) need cutting-edge solutions to meet the challenges of increased and centralized electricity consumption combined with the aging infrastructure. Enter Exel Composites’ carbon fiber composite cores — a revolutionary technology that increases transmission capacity, enhances efficiency, decreases transmission losses, and reduces environmental impact.

Advanced conductors also known as HTLS (High Temperature Low Sag) conductors with composite cores outperform traditional ACSR conductors, making them the preferred choice for modern power grids. Learn how we can help future-proof your electrical infrastructure with composites.

Why choose HTLS composite conductors?

Upgrade aging infrastructure

Over 40% of Europe’s overhead power lines are more than 40 years old, struggling to meet today’s electricity demands. HTLS conductors with Exel’s composite cores modernize existing lines through reconductoring; boosting grid capacity and efficiency without costly new construction.

Eliminate transmission bottlenecks

Building new power lines is a time-consuming regulatory challenge, especially in densely populated areas. Additional challenges are brought by the fast implementation of renewable power plants. Reconductoring with Exel’s composite cores offers a fast-track solution to increase transmission capacity even sectionally while using the existing infrastructure.

Power longer distances with less loss

Renewable energy and urban expansion demand efficient long-distance transmission. Exel’s carbon fiber composite cores support high-voltage applications, minimizing energy loss for a smarter, more sustainable grid.

Support the growth of renewable energy

Wind and solar farms are becoming more widespread and change the layout of the grid rapidly. HTLS composite conductors boost capacity to accommodate these decentralized energy sources without overhauling existing networks.

Stay compliant & reduce carbon footprint

Stricter regulations require maintaining sag clearances at elevated temperatures. Exel’s minimal-elongation composite cores help TSOs meet compliance standards while cutting line losses by up to 50% — resulting in lower emissions and energy savings.

Exel Composites’ conductor core offering

Exel Composites’ innovative composite conductor cores provide a high-performance, cost-effective solution for modern power grids. By replacing traditional steel core conductors with ones having carbon fiber reinforced cores, utilities can significantly improve transmission capacity and efficiency without the need for completely new infrastructure. Our composite cores are stronger, lighter, and safer – resulting in more efficient conductors. Use of composite core conductors enables lower energy losses and minimal sag in the grid, while supporting longer spans between towers. This allows TSOs to increase capacity and enhance grid resilience while reducing maintenance and operational costs.

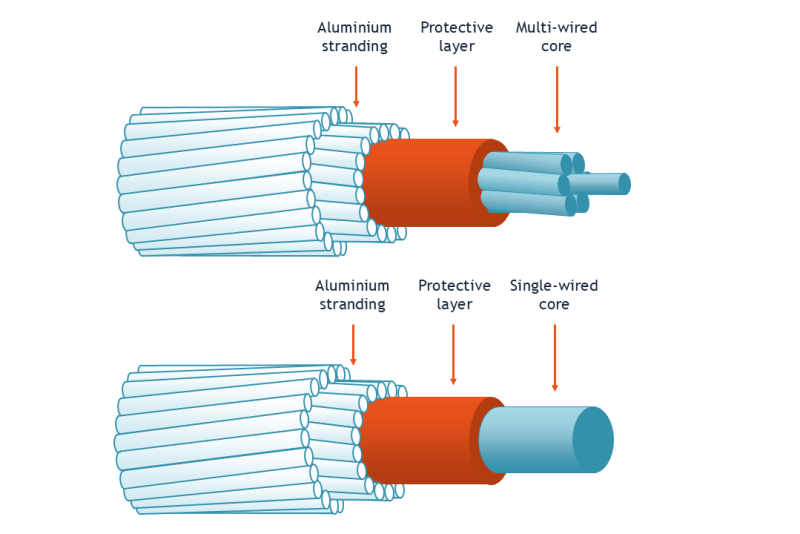

Multi-wire and single-wire PMC conductor cores

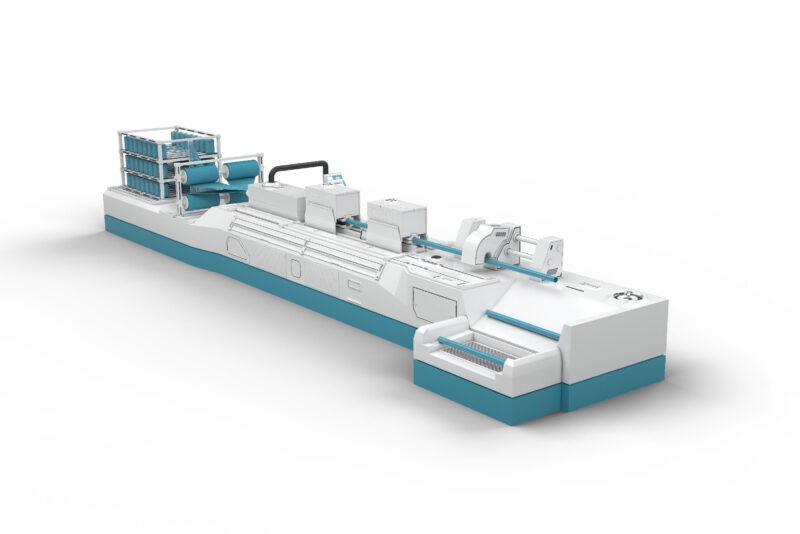

Exel Composites’ Polymer Matrix Composite (PMC) cores are pultruded, spoolable carbon fiber rods, designed for use in both multi-wire and single-wire core structures. Our continuous pultrusion manufacturing technology enables efficient, high-quality production of long-length, spooled products, offering an optimal balance of strength, flexibility, and minimal thermal elongation. These properties make our cores the preferred choice for reliable, long-lasting power transmission. Learn more about pultrusion here.

Single-wire vs. multi-wire cores

While single-wire cores remain the most economical option, multi-wire cores are gaining popularity among TSOs. Traditional carbon fiber single-wire cores require careful handling during installation, as they can be prone to breakage, if mishandled. In contrast, multi-wire cores provide enhanced flexibility, allowing them to behave similarly to traditional steel-core conductors, making installation safer and eliminating the risk of damage.

Exel Composites has decades of technical expertise to support TSOs and conductor manufacturers with different core options. To share this knowledge and shape the common future of power grids, we also take actively part in industry committees of IEC and CIGRE.

Key benefits of composite conductor cores

More capacity

~2x more transmission capacity without major expansions.

Less losses

Transmission loss reduction of up to 50%, lowering operational costs and environmental impact.

Stronger product

50% stronger than steel with virtually zero elongation, reducing sag and allowing for longer spans.

Lower infra costs

Lower infrastructure costs by enabling reconductoring instead of building new lines.

Fast installation

Faster installation and permitting, reducing project delays and regulatory challenges.

Download our composite conductor core whitepaper

Want a deeper look into the benefits of carbon fiber composite cores?

Our free whitepaper, “Accelerating grid modernization with composite conductor cores,” explains how HTLS conductors with composite cores boost capacity, reduce sag, and improve efficiency compared to traditional steel-reinforced solutions. Access the material here to explore key performance data, installation insights, and the role of multi-strand cores in safer, more flexible grid upgrades.

Customizable and high-quality production with pultrusion

Our composite core offering is fully customizable in terms of size, shape, and performance characteristics. With decades of expertise in composite materials, Exel provides tailored solutions, ensuring:

- Typical Tg values of 210-215°C for adjusted operating temperatures

- Tensile strengths exceeding 3000 MPa

- Flexible, global manufacturing capacity to meet project-specific demands

By combining carbon fiber (CF) or hybrid carbon and glass fiber (CF/GF) epoxy matrix designs, we provide solutions that fit the unique needs of conductor manufacturers and TSOs alike.

Our conductor core production lines are fully specified and designed for continuous, high-quality manufacturing. The continuous pultrusion process is constantly monitored, ensuring full traceability of all the reels shipped out from our sites. Read more about pultrusion here.

Grid upgrades made easy with reconductoring

Reconductoring means replacing old power lines with new, higher-performance conductors—without changing the existing towers or routes. It’s a fast, cost-effective way to increase transmission capacity using the grid you already have.

At Exel Composites, we supply carbon fiber composite conductor cores that make this possible. Lighter and stronger than steel, our cores enable HTLS (High Temperature Low Sag) conductors that:

- Carry more power

- Reduce line sag

- Cut transmission losses by up to 50%

Read more about reconductoring with composite cores in this article here.

Case Study: Advanced conductors by De Angeli Prodotti

De Angeli Prodotti, a global leader in electrical conductors, partnered with Exel Composites to develop high-performance carbon fiber conductor cores that help utilities boost grid capacity—without building new lines.

By replacing steel with carbon fiber, the advanced conductors can double ampacity while maintaining sag compliance, even at high temperatures. Unlike new infrastructure projects that can take a decade, reconductoring with Exel’s composite cores takes just 12–24 months.

Key benefits:

-

Faster grid upgrades without new towers

-

Higher ampacity for increased capacity

-

Lower energy losses and emissions

-

Improved safety with multi-wire cores

-

Proven support for modernization goals

This partnership shows how composite cores can deliver a faster, cleaner, and more cost-effective grid.

Read the full case study about De Angeli Prodotti and their advanced conductors here >>

Why carbon fiber composite cores are the future

Carbon fiber composite cores are redefining power transmission by offering higher capacity, exceptional strength, and long-term durability. Their lightweight structure allows for increased aluminum content and use of better conducting aluminum grades, enhancing overall transmission capacity and efficiency. Unlike traditional materials, carbon fiber composites resist thermal expansion, ensuring consistent performance and low sag under extreme temperatures. As a conclusion, these cores significantly reduce maintenance costs while maximizing grid reliability.

As the energy industry shifts toward more sustainable solutions, carbon fiber composite cores stand at the forefront of modern grid advancements.

Why work with Exel Composites?

Carbon fiber composite cores redefine what is possible in power transmission. Greater capacity, unmatched efficiency, and lower costs make Exel Composites the ideal partner for your electrical grid modernization.

With decades of expertise in pultruded composite solutions, we provide TSOs and conductor manufacturers with reliable, high-performance composite cores — engineered for the future of power transmission.

Our continuous pultrusion manufacturing expertise ensures high-quality, with consistent performance, strength, and durability. This scalable production method allows us to meet growing industry demands efficiently, supporting the global transition to more sustainable and robust power infrastructure.

Let’s power the grid of tomorrow with composite cores— get in touch with us today!

Driving standardization in composite conductor technology

At Exel Composites, we actively contribute to the development of international standards that shape the future of transmission infrastructure. Our team works closely with industry associations such as the International Electrotechnical Commission (IEC) and the International Council on Large Electric Systems (CIGRE) to advance the safe, efficient, and reliable use of composite materials in overhead conductors.

Through our participation in technical committees and working groups, we share our deep expertise in composites, pultrusion manufacturing, quality assurance, and long-term performance testing to support the standardization of composite conductor cores.

Most recently, Exel played a key role in the development of IEC TS 62818-1, the first global technical specification for composite conductor core standardization.

Safe installation of composite conductor cores

When installing advanced conductors with carbon fiber composite cores, correct handling is essential to maintain performance and avoid damage. This video explains the key differences between single-strand and multi-strand composite cores and provides practical guidance for safe and efficient installation.

You’ll learn:

-

How single-strand (single-wire) cores, made from pultruded carbon fiber rods, provide exceptional strength but require careful handling due to limited flexibility

-

How multi-strand (multi-wire) cores offer improved bending behavior, allowing the use of standard installation equipment and increased resilience in the event of strand damage

-

Why selecting the right core type and observing proper bending radii are critical to ensuring safety and line reliability

Watch the video to see how Exel’s conductor core solutions are engineered for secure and practical installation in real-world grid applications.

FAQs

Q1: What is a composite conductor core?

A: A composite conductor core is a central structural component of an overhead electrical conductor made from advanced materials such as carbon fiber reinforced polymer (CFRP), rather than traditional steel. Composite cores provide higher strength, lower weight, and minimal thermal expansion, enabling better performance in modern power transmission systems.

Q2: Is conductor core the same thing as a cable core?

A: Not quite. In electrical transmission terminology, conductors typically refer to uncoated wires used in overhead lines, whereas cables are usually insulated or coated and employed in installations such as underground or underwater transmission systems. However, the distinction can become blurred, especially across different languages where translations may vary or overlap.

Additionally, composite rods, made from materials like carbon or glass fibers, can serve as structural components in both conductors and cables, depending on the application.

Q3: Why are carbon fiber composite cores used in HTLS conductors?

A: Carbon fiber composite cores are ideal for HTLS (High Temperature Low Sag) conductors because they offer:

- Minimal thermal elongation

- High tensile strength

- Lightweight structure

These properties enable HTLS conductors to carry more power with less sag, even at elevated temperatures, making them well-suited for grid modernization and renewable energy integration.

Q4: How do composite cores compare to steel?

Carbon fiber composite cores are significantly lighter and stronger than steel, with up to 50% higher tensile strength and minimal thermal elongation. Unlike steel, they do not sag at high temperatures or creep over time, enabling higher operating temperatures and improved clearance compliance. Their low weight also allows more conductive aluminum to be used in the conductor, helping to double transmission capacity and reduce energy losses by up to 50% compared to traditional steel-core ACSR conductors.

Q5: How do composite conductor cores reduce transmission losses?

A: Composite cores enable conductors to operate at higher temperatures with reduced sag, allowing for increased aluminum content or use of better conducting aluminum grades. This improves conductivity and reduces electrical resistance in the conductor, cutting transmission losses by up to 50% compared to traditional ACSR conductors.

Q6: What is reconductoring and how does it benefit TSOs?

A: Reconductoring is the process of replacing existing power lines with higher-capacity conductors, without building new towers or routes. Exel’s composite conductor cores make reconductoring faster and more cost-effective, helping TSOs upgrade grid capacity while remaining existing infrastructure.

Q7: What’s the difference between single-wire and multi-wire composite cores?

A: Single-wire also known as single strand composite cores are cost-effective but require careful handling during installation. Multi-wire also known as multi strand cores or stranded composite cores, offer greater flexibility and resilience, mimicking the handling behavior of traditional steel core conductors (ACSR) and reducing the risk of breakage during installation and use. Exel offers both options, customized to project needs.

Q8: Are HTLS composite cores safe during installation?

A: Yes. Multi-wire cores, in particular, offer strong bending tolerance (~300 mm diameter) and can even sustain partial damage without complete loss of tensile strength. This ensures integrity during installation and reduces costly downtime or maintenance later.

Q9: How does Exel Composites manufacture composite conductor cores?

Exel uses continuous pultrusion technology to produce high-performance carbon fiber rods. This method combined with a strict quality system, ensures consistent quality and full traceability with customizable properties.

Q10: How is Exel Composites involved in conductor core standardization?

Exel actively contributes to international standards development through organizations like IEC and CIGRE. Most recently, Exel played a key role in creating IEC TS 62818-1, the first global specification for composite conductor core standardization, supporting safe, reliable, and efficient transmission systems. This document specifies, for example, the terminology including PMC Polymer Matrix Composite cores.

Q11: What are the key benefits of Exel’s composite conductor cores?

- 🟢 Up to 2× more transmission capacity

- 🔻 Up to 50% lower energy losses

- 💪 Stronger than steel with virtually no sag

- 🛠️ Enables cost-efficient reconductoring

- ⚡ Faster permitting and installation

- 🔄 Customizable design and scalable production