Standard composite structural profiles featuring pultruded GRP and fibreglass structural shapes

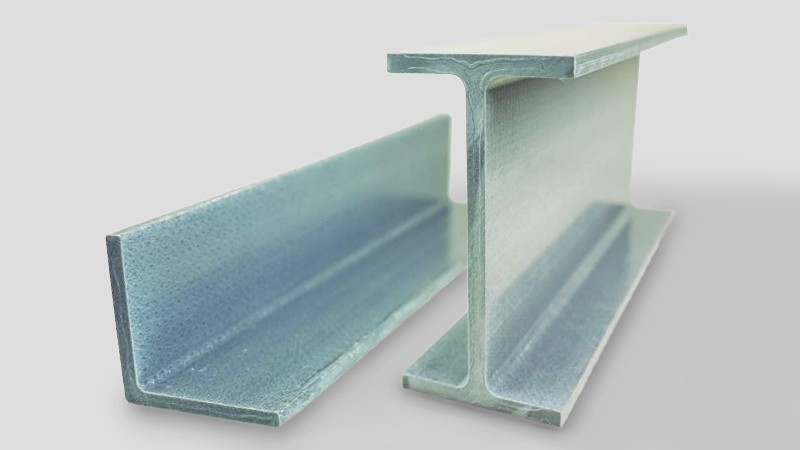

Exel Composites' standard structural composite profiles include pultruded I-beams, channels, angles, tubes, box profiles, and various other composite structural shapes. For over 40 years, our fiberglass structural shapes and FRP composite profiles have been successfully used in numerous applications and access structures. These composite profiles are excellent alternatives to traditional materials like metal or wood, particularly in harsh environments prone to rotting, rusting, and corrosion. We offer over 60 different structural profiles and shapes, all stocked and ready to ship from our European factories. Inquire about our inventory or request a quote by filling out the contact form below.

Standard Pultruded GRP and Fiberglass Structural Shapes Ready to Ship Now

Exel Composites is your go-to source for an extensive range of high-quality composite structural profiles and fibreglass structural shapes, including I-beams, boxes, channels, angles, tubes, sections, ladder systems, and handrail systems. We maintain an inventory of over 60 different structural pultruded profiles in our European factories, ready to ship and ensuring a robust selection for your immediate needs.

Every structural profile and pultruded shape we offer meets or exceeds the mechanical and aesthetic requirements of European Standard EN 13706 E23 and ASTM D4385. Additionally, our composite profiles are manufactured in line with the quality assurance standards of BS EN ISO 9001.

Composite profiles are renowned for their lightweight, UV-stabilised properties, which require minimal maintenance and offer excellent corrosion resistance. These attributes make them a cost-saving material option. Whether used in construction or industrial applications, our advanced pultruded profiles are engineered to provide superior durability and reliability, even in the most challenging conditions.

Check out our FAQ section below to learn more about the benefits and features of Exel’s structural composite profiles for your construction projects.

Our range of standard structural profiles includes

Angle

Composite structural profiles

Box

Composite structural profiles

Channel

Composite structural profiles

I-beam

Composite structural profiles

Ladder systems

Composite structural profiles

Handrail systems and tubes

Composite structural profiles

Solid sections

Composite structural profiles

Accessories (end caps, mounts)

Composite structural profiles

Durable and Aesthetic Pultruded GRP and Fibreglass Structural Shapes

Our composite structural profiles are predominantly stocked in a standard grey color based on RAL 7001. For projects requiring a different aesthetic, we also offer profiles in yellow (RAL 1023). We ensure color consistency by monitoring the CIELAB Delta E, providing a product that is not only functional but also visually appealing.

Safety and durability are key features of our pultruded profiles. These fiberglass structural shapes are certified with a fire rating of EN 13501-1 Euroclass E, ensuring peace of mind in demanding applications. Additionally, our GRP pultruded profiles exhibit exceptional chemical resistance: they do not rot and are impervious to a wide array of corrosive environments. For applications requiring enhanced chemical resistance, we offer profiles made with vinyl ester resin. Detailed information is available in our corrosion resistance guide, or you can contact us to discuss your specific requirements.

Our structural profiles and FRP shapes are manufactured using the pultrusion process, an efficient and continuous method for producing composites. This technique ensures consistent quality, high-volume production capabilities, minimal waste, and reduced labor costs. As a result, each structural profile and shape maintains superior performance and durability, effectively meeting the diverse needs of various industrial and commercial projects.

Advantages of Structural Composite Profiles for Construction and Infrastructure

Durable – UV and Chemical Resistance: Fiber-reinforced composite profiles resist UV radiation and various chemicals, maintaining their structural integrity and appearance in harsh environments for long-lasting durability.

Lightweight – 4 Times Lighter Than Steel: Exel’s composite profiles are up to four times lighter than steel while offering equivalent strength, making handling, transportation, and installation easier and more cost-effective.

Strong – Exceeding Strength Requirements: Our structural composite profiles typically offer double the strength required by the E23 classification, ensuring robust and reliable structural support under demanding conditions.

Stiff – High Tensile Modulus: With a tensile modulus typically exceeding the E23 classification by 25%, composite structural profiles provide superior stiffness, maintaining shape and structural integrity under load.

Low Thermal Conductivity – Excellent Insulation: Fibreglass structural shapes exhibit low thermal conductivity compared to metal, enhancing insulation and energy efficiency by minimizing heat loss.

Thermal Efficiency – Minimizing Heat Loss: The thermal efficiency of our pultruded profiles reduces heat loss, contributing to energy conservation and lower heating and cooling costs.

Thermally Stable – Low Coefficient of Thermal Expansion: Our standard structural profiles have a coefficient of thermal expansion six times lower than uPVC and half that of aluminum, ensuring minimal expansion and contraction with temperature changes.

Low Electrical Conductivity – Insulating Properties: Made with glass fiber, our profiles have low electrical conductivity, ensuring safety in applications requiring electrical insulation.

Dimensionally Stable – High Stiffness and Thermoset Resin: The combination of high stiffness and thermoset resin ensures our profiles maintain their integrity and performance over time, even under varying environmental conditions.

Corrosion Resistant – Weathering Resistance: Pultruded structural profiles resist weathering, corrosion, and chemical exposure, extending their lifespan and reducing maintenance needs.

Low Maintenance – No Rot, Rust, or Swell: Unlike traditional materials, composite profiles do not rot, rust, or swell, resulting in reduced maintenance costs and less frequent interventions.

Lasting Performance – Moisture and UV Resistance: Moisture-resistant and UV-stabilized, our structural profiles and shapes ensure consistent long-term performance.

Non-Magnetic and Radio Frequency Transparent: Non-magnetic and radio frequency transparent, our profiles are ideal for applications where minimizing electromagnetic interference is important.

Machinable: Easily machined using standard equipment, our composite profiles offer versatile customization and easy project integration.

Easy Installation: The lightweight nature permits lifting into position with less equipment.

High-Quality Pultruded GRP and Fibreglass Structural Shapes Meeting European Standards

Our profiles are crafted from high-quality glass fiber combined with a UV-stabilized isophthalic resin. This innovative construction process involves using direct glass rovings, constructed mats with off-axis fiber, and a polyester surface veil. These meticulous manufacturing techniques ensure that our profiles adhere to the rigorous European Standard EN13706 E23, with profiles less than 5mm thick meeting the E17 criteria. Understanding the standards like EN 13706 and E23 is crucial.

EN 13706 outlines the prerequisites for structural pultruded profiles, especially where load-bearing characteristics play a pivotal role in design and function within a load-bearing system. The E23 classification signifies a minimum Full Section flexural modulus of 23GPa and an average axial tensile modulus of 23GPa across five valid tests. Our profiles not only meet but often exceed these minimum requirements, typically achieving a modulus of 30GPa and an axial tensile strength of 500MPa (considerably higher than the minimum requirement of 240MPa)

Our profiles are made to meet or exceed the requirements of EN13706 E23* European standard for structural pultrusions

Test |

Units |

Test Standard |

|

E23 minimum Properties |

|---|---|---|---|---|

| Full section bend test | GPa | Annex D, EN 13702-2 | 23 | |

| Tensile modulus – lengthwise | GPa | EN ISO 527-4 | 23 | |

| Tensile modulus – crosswise | GPa | EN ISO 527-4 | 7 | |

| Tensile strength – lengthwise | MPa | EN ISO 527-4 | 240 | |

| Tensile strength – crosswisse | MPa | EN ISO 527-4 | 50 | |

| Flexural strength – lengthwise | MPa | EN ISO 14125 | 240 | |

| Flexural strength – crosswise | MPa | EN ISO 14125 | 100 | |

| Interlaminar shear strength – lengthwise | MPa | EN ISO 14130 | 25 | |

| Pin-bearing strength – lengthwise | MPa | Annex E, EN 13702-2 | 150 | |

| Pin-bearing strength – crosswise | MPa | Annex E, EN 13702-2 | 70 | |

| Fire classification | BS EN 13501-1 | Euro Class E |

*<5mm thickness E17

*Minimum properties are based on the average value of 5 valid tests

Frequently asked questions about standard structural composite profiles (FAQs)

Q1: What type of structural composite profiles does Exel manufacture?

Exel offers a standard range of composite structural profiles, including pultruded I-beams, channels, angles, tubes, and box profiles. We also create custom profiles tailored to your specific requirements.

Q2: What standard structural composite profiles do you have in stock?

Our standard range of structural composite profiles includes over 60 different fibreglass shapes that are kept in stock and ready to ship. These pultruded profiles are made of glass fibre with a UV-stabilized isophthalic resin, utilizing a combination of direct glass rovings, constructed mats incorporating off-axis fibre, and a polyester surface veil. The profiles are designed to meet the European Standard EN13706 E23 (E17 for thicknesses less than 5mm).

Q3: What do EN 13706 and E23 mean?

EN 13706 is the European standard that outlines the criteria for structural pultruded profiles, focusing on their load-bearing characteristics as a major design criterion and their role as part of a load-bearing system (EN13706-2:3.3). It covers aspects like appearance, dimensional tolerance, and workmanship. E23 refers to a minimum full-section flexural modulus of 23 GPa and an average axial tensile modulus of 23 GPa when five valid tests are performed. This is a minimum value, and our profiles typically achieve a modulus of 30 GPa. The minimum axial tensile strength requirement is 240 MPa, with our profiles typically achieving 500 MPa.

Q4: What colour are your standard profiles?

Our standard structural profiles are generally stocked in grey, with some profiles available in yellow. They are based on RAL 7001 grey and RAL 1023 yellow, with the primary colour reference based on a standard visual sample. We monitor the CIELAB Delta E for colour consistency.

Q5: Do your structural composite profiles have a fire rating?

Yes, our standard structural composite profiles are certified as EN 13501-1 Euroclass E.

Q6: What is the chemical resistance of the structural profiles?

Our standard GRP pultruded profiles will not rot and are impervious to a broad range of corrosive environments. For applications requiring extended chemical resistance, we offer profiles made with vinyl ester resin. Please refer to our corrosion resistance guide or contact us to discuss your specific requirements.

Q7: What manufacturing process do you use to make the structural profiles?

Our structural composite profiles are manufactured using the pultrusion process. Pultrusion is a continuous manufacturing method for composites, ensuring consistent quality, high-volume production, minimal waste, and reduced labor costs.

How FRP Structural Profiles Are Revolutionizing Energy-Efficient Building Solutions: Insights from Exel Composites’ Expert

The building, construction, and infrastructure (BCI) sector increasingly relies on fiber-reinforced plastics (FRP) for applications like window frames, structural supports, and piping. Kim Sjödahl, Exel’s Senior VP of Technology and Sustainability, discusses how FRP meets modern technological and environmental demands. Composites offer thermal stability, effective insulation, and exceptional longevity, making them ideal for energy-efficient buildings. Pultrusion and pull-winding manufacturing processes ensure high-quality, cost-effective production. Despite some industry hesitation, pre-machined composite kits simplify adoption. Read the full story here.