Crafting Durable Tool Handles with Fiberglass Rods and Carbon Fiber Tubes for Cleaning, Maintenance, and Construction

From mop and broom handles to hovels and hammers, tool handles must deliver reliable performance through constant, demanding use. To meet these expectations, manufacturers are increasingly turning to advanced composite materials like fiberglass and carbon fiber. We produce handles that are not only lightweight and strong but also built for ergonomic comfort.

All-Day Performance Starts with Composite Tool Handles

In industries where tools are used from dawn to dusk, comfort, strength, and reliability are essential. Composite materials like fiberglass and carbon fiber rods offer the ideal combination of lightweight performance, durability, and ergonomic design—making them a smart choice for tool handles.

Our composite handles are used in a wide range of cleaning and construction tools—from carbon fiber handles on window-washing telescoping poles, to fiberglass handles on commercial mop systems, to non-conductive tool handles used by electricians and utility workers. Landscapers rely on FRP handles (fiber-reinforced polymer) for shovels and rakes that can withstand rugged outdoor use, while industrial technicians benefit from custom composite handles designed for hot stick rods and inspection equipment.

We specialize in continuous manufacturing processes that ensure consistent quality and scalable volume output. Whether you need a custom composite handle with a threaded insert, a grip-ready surface, or a pre-installed connector, we deliver precision and repeatability at every stage.

Key benefits

High quality, smooth surface

We offer a range of surface finishes to provide the right hand-feel, enhancing grip and comfort while adding durability and style to each composite tool handle.

Stiffness and strength

We work with you to cost-effectively engineer FRP tubes and fiberglass tool handles that meet your specific strength and stiffness requirements—delivering lightweight durability that reduces fatigue and performs reliably in demanding outdoor environments.

Secondary processing

Need a threaded end, hand grip, or pre-installed connector? We’ve got you covered. Our composite tool handles can also include an anti-bacterial silver ion additive—ideal for hygiene-critical settings like food prep and healthcare.

Engineered for Performance. Customized for You.

Composite materials like fiberglass and carbon fiber are rapidly becoming the go-to choice for tool handles due to their superior strength-to-weight ratio, corrosion resistance, and excellent damping properties. These qualities make them ideal for a wide range of tools used across various industries.

For example, in tools like hammers or impact devices, carbon fiber handles effectively absorb vibrations and shocks. When a worker strikes with such a tool, the composite handle minimizes the shock transferred to the wrist and arm, enhancing comfort and reducing fatigue or strain during prolonged use. This not only improves the user experience but also contributes to greater workplace safety and productivity.

Whether you need an ergonomic handle or a lightweight rod for extended reach, our composite tool handles are engineered to meet your exact specifications.

Our tube and rod production facilities are located in Europe, the USA, and Asia. This global footprint enables us to serve customers across continents with speed and efficiency, ensuring shorter waiting time and reliable delivery worldwide.

Standard handle diameter (outer/inner) |

Min length |

Max length |

| 22/18 mm (0.87″/0.77″) | 600 mm | 2000 mm |

| 23.5/20.5 mm (0.93″/0.81″) | 600 mm | 2000 mm |

| 25/22 mm (0.99″/0.87″) | 600 mm | 2000 mm |

| 25.4/22 mm (1.0″/0.87″) | 600 mm | 2000 mm |

These are our standard composite handle dimensions. We also work with you on custom sizes, please contact us to find out more. The typical minimum order quantity is 1500 pieces.

We make it easy for you

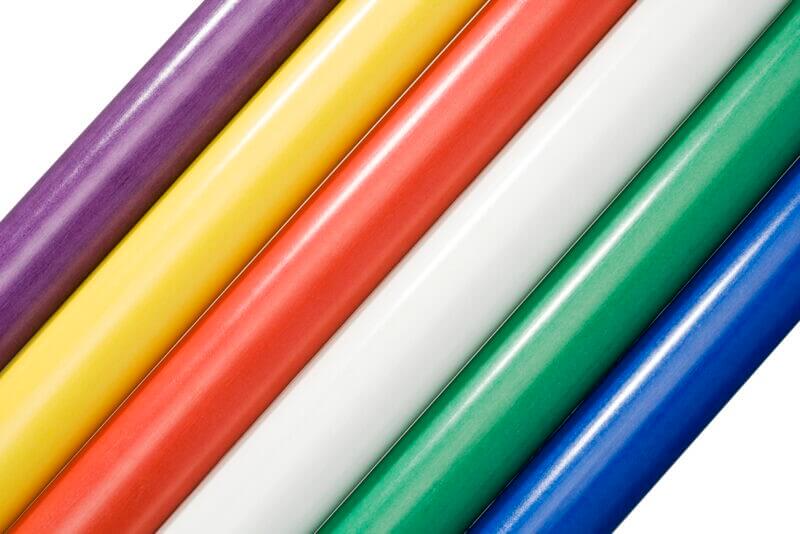

Start by selecting your handle. Next specify the color (the pigmentation is added to the resin, ensuring the color is consistent throughout the product, and is long lasting). Then let us know if you need end grips or thread attachments, and if you require any secondary processing such as holes or printing.

You can even specify the type of packaging used when we deliver; from plastic wrapped to cardboard to plastic ties.

Additional features

We can also include an anti-bacterial (silver ion) additive to the resin for tool handles that help reduce bacteria. These types of handles are most commonly found in areas where higher hygiene is important, such as food preparation or in the health care industry. The tool handles can be sterilized using standard autoclave processes

Versatile Applications of Carbon Fiber Tool Handles Across Industries

As industries push for more specialized, high-performance tools, the use of carbon fiber handles, fiberglass handles, and pultruded fiberglass rods is rapidly expanding. This surge is fueled by the growing demand for materials that enable longer reach, precise control, and the inherent non-conductive properties of carbon fiber composites—crucial for safety in electrical applications. From electrical utilities to agriculture, tool manufacturers are increasingly adopting carbon fiber tubes, fiberglass telescopic rods, and custom composite handles to unlock new capabilities and maintain a competitive edge. This marks a broader shift in industrial tool design, where tailored, application-specific solutions—like the modern industrial tool handle—are setting the new standard across maintenance, cleaning, construction, and forestry sectors.

Electrical Maintenance

With their non-conductive properties and exceptional strength, glass fiber handles are a trusted choice for electrical applications where safety and extended reach are essential:

- Telescoping hot sticks for high-voltage line servicing

- Insulated extension poles for overhead inspections

- Live-line tools for fuse replacement and switch operation

- Voltage detector poles and disconnect tools for energized systems

Cleaning and Maintenance

Rods and tool handles made from carbon fiber materials significantly reduce user fatigue due to their lightweight yet rigid construction—especially beneficial for tools requiring extended reach. Their durability and resistance to harsh environments make composite tool handles an excellent choice for cleaning applications involving repetitive or overhead tasks:

- High-reach dusters and scrubbing tools for both interior and exterior surfaces

- Pressure washer wands for industrial and commercial cleaning

- Floor scrubber and mopping handles for large-area maintenance

- Pool maintenance poles for skimming, brushing, and vacuuming

Agriculture and Forestry

In demanding outdoor environments, carbon fiber handles provide the durability and ergonomic advantage needed for long hours of fieldwork:

- Palm tree harvesting tools for high-reach fruit collection

- Tree pruning poles and saws for orchard and forestry care

- Fruit picking poles for delicate, elevated harvesting

- Vineyard maintenance tools for canopy management and upkeep

- Inspection rods for monitoring tree health and pest control

Through our specialized manufacturing capabilities, we deliver custom composite tool handles tailored to meet exact performance and design requirements. From cleaning tools to industrial equipment, our fiberglass and carbon fiber handles offer the strength, comfort, and durability professionals rely on. Built to perform and made to last, our handles help manufacturers and end users work more efficiently—day in and day out.